How Biogas Plant works?

Energy is biggest crisis all over the world, and particularly for farmers in rural areas of India Pakistan, Philippines, China etc., deforestation increasing day by day and the availability of fuel to decrease to the point that energy very important for the most basic needs of cooking for home. |

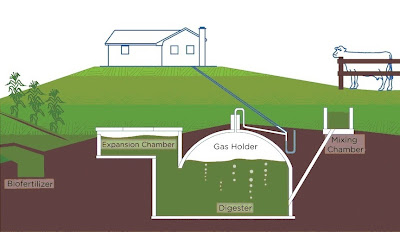

| Model Of Biogas Plant Large Photo |

Fortunately, most villagers have the answer to energy problem on their very own farms. Farmers who own buffalos cows, and chickens can collect the waste from these animals The waste digest under oxygen free environment and creates gas that is use for cooking, lighting, heating etc. and the processed animal waste called slurry is a very organic nutritious fertilizer that has increase doubled crop yield for biogas plant users.

By installing a biogas system, the farmer produces two very important products: biogas to replace unreliable, unhealthy and expensive fuels, and biofertilizer or organic nutritious fertilizer to replace expensive and harmful synthetic fertilizers and increase their crop yield by farming the same amount of land.

Biogas Plant has main two common type in the world, 1st is Movable dome biogas Plant and 2nd is Fixed dome plant these plant working are same but the storage of gas is different.

What is the feed of Biogas Plant”

Organic Waste:

Organic wastes such as human feces, cow dung, vegetable scraps, greases, green waste…really anything that can rot can be used to produce biogas. The waste is mixed with water and loaded into an anaerobic digester. The digester maintains an oxygen-free environment suitable for methane-producing archeabacteria (also called methanogenic bacteria) to metabolize proteins, lipids and carbohydrates in the waste into biogas.BIOGAS:

The biogas is approximately 65% methane and 35% carbon dioxide and several other gases at low concentrations. The anaerobic digester collects the biogas as it bubbles to the surface.

DIGESTATE:

After the bacteria have consumed the energy from the waste there are still leftover solids. This digestate contains little pathogenic bacteria, if any at all. The digestate can be used as an organic agricultural fertilizer at a much lower price than the chemical fertilizers.

FERTILIZER:

Organic fertilizer from digestate also contains more micronutrients than chemical fertilizer, which will replenish the soil for long lasting soil fertility.

.jpg)